It is designed to produce coating slurry by mixing small batch of chemical and compound (500 ml Max) under vacuum to remove gas bubble and protect sample from oxidation. It has build-in pump which can vacuum the mixing container to 0.08Mpa and the step- less mixing speed variates from 0 to 320rpm. The vibration plate is located at the bottom to remove gas bubble before vacuum mixing and disperse the slurry after mixing to ensure better uniformity. It is excellent for preparing battery electrode paste and various ceramic materials in research lab.

Specifications:

-

- Voltage Input: Single Phase 220VAC 50/60Hz

- Power: 150W

- Rotary Speed: 320 rpm

- Mixing Container:

- One 150ml stainless steel and one 500ml aluminum container are included.

- Vacuum pump: Built in

- Vacuum Level: 0.08~0.09 Mpa

- Vibration Plate: Vibrating at 1000 Hz

- Dimension: 13”L x 12”W x 21”H

- Shipping Dimension:16”L x 15”W x 24”H

- Net Weight: 70 lbs

ne battery machine

ne battery machine

1.mixing tank

Inner size: Φ260x180mm(designing volume 5L),barrel clamp,inside and outside stainless steel(sus304)

suitable slurry viscosity: 1000-1000000cps

2.design volume: 9.5L,working volume: 5L

3.mixing paleta: espiral

4.mixing frequency motor 0.75Kw

5.mixing motor power: 0.75KW

6.mixing propeller rotate speed: 0-117 rpm -2set(frequency control)

7.scape rotate speed: 0-85 rpm -1set(frequency control)

8.disperse rotate: 0-3000rpm -1set(frequency control)

Disc diffuser in the form of teeth

9.disperse frequency control: 1.5KW

10. disperse motor power: 1.5KW

11.lifting stroke: 300mm

12.total power: about 3KW

13. machine weight: about 360kg

14.outside size: L 1000m xW330mm x H1100mm

Omni-Directional Planetary Ball Mill

Description:

This is an omni-directional planetary ball mill used as preparation device for mixing, fine grinding, sample preparation, nanometer material dispersion, new product development and small batch production of high-tech materials. This product is small in size, full in function, high in efficiency and low in noise. It is an ideal equipment for scientific research institutions, universities, and industries laboratories to obtain microparticle research samples (four samples can be obtained at the same time for each experiment). It is equipped with a vacuum ball milling tank and can grind samples under vacuum.

The omni-directional planetary ball mill is suitable for wet and dry crushing and refining of hard, medium hardness, brittle and fibrous materials. The sample fineness can be less than 100 nm. It can also be used for grinding of solids in suspension, sample mixing and homogenization, and metal alloying, which can achieve ideal and outstanding results.

Working principle:

- Under the influence of the geometric structure of the grinding carrier and the special motion mode of the high frequency and high intensity collision, shearing and friction directly generated by the grinding medium and the sample make the sample achieve extremely excellent grinding effect, with the characteristics of fast processing speed, small, uniform.

- The material as a whole is far away from the revolution center in a group way, and after rotating to a certain angle with the cylinder, it slides in the opposite direction of rotation. The grinding body pushes the powder layer away from the mill and exerts compression, shear and friction on the material.

- After the material is turned to a certain angle with the grinding cylinder, the pressure on the cylinder wall is equal to zero, and the material is thrown off the cylinder wall, exerting an impact on the material.

- The material rises along the concentric circle track, and then falls down layer by layer in a circular flow state. It exerts extrusion grinding and friction on the powder.

- The material moves in a circle with the grinding ball and slides relative to it, exerting friction on the powder.

- The material at the cylinder wall does not slide and rotate with the grinding cylinder, thus losing the crushing effect, but can be used to protect the inner wall of the grinding cylinder and reduce wear. Among them, circulation and sliding motion play a major role in fine crushing.

- 360-degree rotation. When the planetary tank body is working, the planetary main plate will rotate continuously 360 degrees or work at any angle, so that the material can fully participate in the grinding. This type is also known as the non-dead angle planetary grinder.

Specifications:

- Electrical Description: 200-240V AC, 50-60Hz, 0.75 kW

- Material Feed Size: Brittle materials are less than 10mm, others are less than 3mm

- Final Fineness: <100 nm

- Grinding method: Dry/wet/high-energy alloying grinding/vacuum grinding

- 360° speed (variable frequency adjustable): 1-14/min

- Speed ratio (revolution:rotation): 1:2

- Planetary speed (variable frequency adjustable): Maximum revolution 0-400r/min, rotation 0-800r/min, Total planetary speed: 1200r/min

- Speed control mode: PLC variable frequency control system and touch screen control system are optional.

- Transmission mode: Gear drive

- Batch Size / Feed Quantity: 4 x 500 ml.

- Grinding Jar Volume Acceptability: 50 ml ~ 500 ml

- Vacuum Jar Volume Acceptability: 50ml ~ 250mL

- operation mode: Two or four tanks work at the same time

- Maximum continuous working time: 72 hours (timer 0-9999h)

- Program control: The ball mill is controlled by high-tech micro-computer chip, and it can run forward and reverse repeatedly (0-999min) and forward, pause, reverse, pause and forward (0-999min) alternately according to the setting procedure, especially suitable for the need for cooling or intermittent operation.

- External dimension: 950mm x 550mm x 650mm

- Weight: 96 Kg

Accessories:

1. 4 × 250 mL Zirconia Jars and Balls

2. 2 × 250 mL SS Jars and Balls

3. 4 × 100 mL Zirconia Jars and Balls

![]()

Product Details

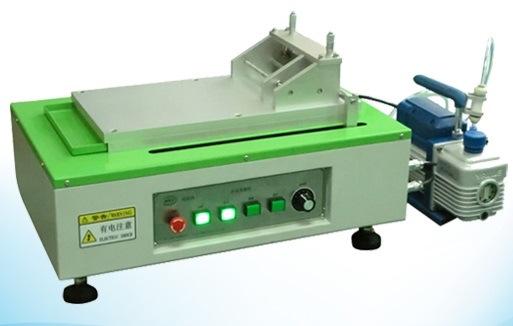

Automatic film coater is a Large Automatic Film Coater designed to produce films with consistent thickness by using micrometer adjustable applicators or fixed thickness applicators. It has an unique driving system to produce smooth coating on all types of materials. One micrometer adjustable applicator is included for immediate use.

Specification:

| ITEM | Data |

| Working Voltage | 220V , 50Hz |

| Feed speed | 0 ~ 100mm/s, the speed can be adjusted |

| Max.Stroke Length | 10 – 250mm adjustable (According to customer request) |

| Vacuum plate | With vacuum aluminum plate |

| Scraper range | 0.01~3.5mm adjustable |

| Vacuum Pump | Yes |

| Product Dimensions | L500mm×W310mm×H200mm |

| Platform Dimensions | L365mm×W200mm×H30mm |

| Net Weight | 50 kg (135 lbs) |

| Warranty | One year warranty and lifetime maintenance |

2. conditions for all coating material

3. Aluminum alloy flat vacuum plate with built in vacuum pump and allow you put on or release substrate quickly

4. Built-i

n pushing bar for using micrometer adjustable applicator or frame film applicator

5. Adjustable position switch allow you set up a stroke from 10 – 250 mm

6. One 150 mm width micrometer adjustable film applicator is included (thickness adjustable from 0.01 – 3.5 mm)

7. Heating cover is built in with digital temperature controller for drying film within 200℃ within +/-1oC.

8. Vacuum pump is not included in the coater to avoid vibration. You can use your own vacuum pump or order optional vacuum pump from us.

9. 3/8 ” ID x 48″ L hose is included for connecting pump and coater.

- Product Details

- 1.Functions:

- The equipment used for the lithium-ion battery cutting electrode

- automatically, the user can set the size of the cut length. It’s mainly consists

- of the drive part, PLC control, cutting device (or automatic discharge device)parts.The drive part adopts motor driver of feed rollers to cut electrode; PLC controlled using a special motor drive can be realized english

- display, length setting, speed setting;the cutting device adopts precision

- mold, the up and down knife mold and pneumatic driven, automatic feeding

- according to the electrode feeding, or according to the coating gap to track

- for electrode cutting,cutting can be set many time

s.

s. - 2.Technical parameters:

- 2.1. power:1KW

- 2.2 cut materials :anode and cathode electrode, or their clearance electrode

- 2.3. cutting range: 500mm

- 2.4. Cutting precision: ± 0.3mm

- 2.5. Speed: 0-12m/min adjustable

- 2.6. unwinding tension adjustment: 12Nm

- 2.7 Dimension:L*W*H=1450*1250*1050mm

- 3.Performance:

- 3.1. This equipment adopts step motor feed drive,high precision of

- fixed-length

- 3.2. PLC control,the english set the length,easy operation,intuitive;

- 3.3. digital set-length of cutting,cut the length of gap tracking;

- 3.4. pneumatic drive,low noise

Product Details

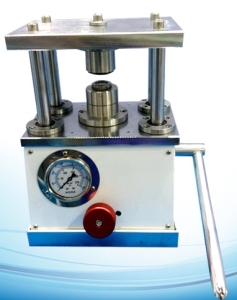

Compact Hydraulic Crimping Machine: One for All Button Cells of CR2016, CR2025, & CR2032 (Optional Die CR1220, CR2325 or CR2450, AG3, AG5) – GN-110

-

-

- It is a newly designed coin-cell crimper with lighter weight and a smaller footprint. The crimper is suitable for sealing various types of coin cells such as CR2032,CR2025,and CR2016 with included die. It can also crimp CR2325, CR2450, AG3, AG5 and other special size cases with optional die sets.

- In addition, customers can easily replace the original die for disassembling purpose.

- It is an ideal tool for operations in a glove box.

-

Specification:

| Standard Crimping Die | One set of crimping dies for all CR20XX coin cell, such as CR2045, CR2032, CR2025 and CR2016, etc. |

| Structure | Heavy Duty Steel plate |

| Pressure | Max. 8 metric Tone hydraulic with automatic return |

| Net Weight | 25Kg |

| Machine overall Dimension | 300L x 190 W x 310H mm |

| Shipping Weight | 35 Kg |

Product Details

It is a ultrasonic metal welder designed for welding stacked electrode sheets (Copper & Aluminum) and tab onto current collectors to prepare Li-Ion pouch cells in R&D laboratories.This welder is suit for max.of 25layers electrodes welding.

SPECIFICATIONS:

| Input Voltage | 220V AC 50Hz |

| Max. Power Consumption | 0-800W |

| Welding Area | 5.2mm(L) x 5.2mm(W) |

| Welding Head | .Two welding heads and three welding bases are includedfor welding both aluminum & copper current collectors from 1 to 25 layers.Two types of patterns for various uses: |

| Ultrasonic Frequency | 30 – 40 kHz Adjustable frequency |

| Pneumatic Control | Air pressure at 85 psig |

| Product Dimensions | · Controller: 365mm(L) x 485mm(W) x 200mm(H)Welder: 300mm(L) x 460mm(W) x 275mm(H) |

| Warranty | One Year limited warranty with lifetime support |

| Net Weight | 61 kg (135 lbs) |

Product Details

- Basic Function and Features:

It is mainly for square power LIB cell’s precisionly winding.

- SPECS

1)Winding needle group width:15-30mm;30-75mm

2)Separator width:80-130mm

3)Electrode width:78-128mm

4)Electrode length:300-1500mm

5)Ending tape width:10-15mm

6)Winding precision: the aligning error between separator and cathode,cathode and anode electrode all less than ±0.5 mm

Requests to materials:

- Electrode width error less than 0.1mm

- Electrode’s S curve error less than 0.5mm/1000mm,also without raise edge phenomenon

- Separator’s turriform error less than ±0.2mm, also without raise edge phenomenon

7)Machine capacity:3-6PPM(related to the length of the electrode and the artificial feeding speed)

8)Drum shell rate:cell thickness<5mm,drum shell rate <2%

Cell thickness>5mm,drum shell rate<3%

3.Supporting facility:

1)Space: 1500 mm(L)×1300mm(D)×1500mm(H)

2)Supply power: 220 VAC±5﹪,Single phase,1 KW

3)Air supply: 5~7 kgf/cm²,100 l/min

4)Non-corrosive gases,liquids,explosive gas

Product Details

I Machine Function and Applying

-

-

- Function:

-

The machine is used to seal Al foil batteries semi-automatically.

-

-

- Applying:

-

Width: 6mm; Length: ≤200mm.

The size can be designed as clients’ requirements.

II Technical Data

-

-

- Voltage: AC220V/50HZ

- Current: 6A

- Power: 2KW

- Air Pressure: ≥0.5KPa

- Weight: 500kg

- Size: 1000MM X 900MM X 1580MM (L*W*H)

-

III. Machine Characteristics

-

-

- The machine is controlled by PLC; the worker can easily operated the machine by the touch screen.

- The machine has two spaces (top & bottom) and a turnplate. Two spaces and a turnplate can make a vacuum space which is for sealing batteries.

- The temperature of sealing heads can be controlled by temperature controller which can set any temperature. And the machine will make warnings when the temperature is over high.

-

Each part is inner of the frame and safe door with the protecting switch and warning function.

SEMI-AUTOMATIC ELECTRODE STACKING MACHINE (MODEL: BS-DP200S)

Description:

This is a desktop semi-automatic electrode stacking machine with advanced features to ensure a stable, repeatable and precise electrode stacking. In its “Z” fashion stacking method, Anode and Cathode electrodes are alternately stacked with the separator film in between.

Features:

- This is a Tabletop type machine has a small and compact footprint. It can be placed on the ordinary desktop.

- Z-shape semi-automatic stacking machine, separator automatic tension control.

- The machine has automatic lifting and placing of the electrodes in the stacking position function.

- Automatic counting of stacking number, manual zeroing, design digital display counter.

- The machine has PLC driven touch screen control for all the functions.

- Electrodes to be placed manually and the fixture is used to assist the positioning to ensure the uniformity of the stacking for different electrode dimensions.

- The machine has a button switch which is adopted to control the operation of the air cylinder and the PLC is driven.

- The machine has an in-built vacuum pump to pick up the electrodes automatically.

- Accommodate a wide variety of electrode dimensions, if needed.

Specifications:

- Alignment accuracy : < 0.5 mm

- Separator width : ≤105mm

- Maximum separator roll : φ200 mm

- Applicable electrode size : L 55 – 100 mm, W 40 – 105 mm, H 2 – 8 mm

- Tab length : ≤25 mm

- Swing roll travel : 180 mm

- Air pressure source : 0.5MPa ~ 0.7MPa

- Input Voltage : AC220V Single Phase, 50 Hz

- Machine Size : L710 mm × W600 mm × H770 mm

- Weight : 80 Kg

- Vacuum pump : In built vacuum pump

Coming Soon….