Furnaces

Anode and Cathode Material Synthesis / Drying and Sintering / Battery Recycling

Muffle Furnace / Tube Furnace / Vacuum Furnace / Electric Arc Furnace

- Furnace materials: Ceramic fiber material

- Heating element: High-temperature resistant and oxidation-resistant

- Maximum temperature range: ≥ 1000 °C

- Vacuum facility / Gas purging facility

- Programmable temperature control system with security protection

Muffle Furnace

Atmosphere Furnace

Tube Furnace

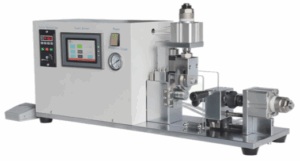

- Consists of a solution buffer tank, a synthesis reactor and aging reactor

- All SS316 structure (optional PFA coating) with temperature control, pH control and feed control system

- Reactor Volume: 5L – 100L

- Hot water bath temperature control 20°C – 95°C (Accuracy ±1°C)

- Two sets of agilator paddles – upper and lower, four blade turbine types, up to 900 RPM

- Feeding ports: Salt solution, Alkaline solution, Ammonia, Water and Standby port

- Touch panel control of all the parameters.

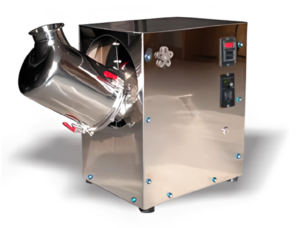

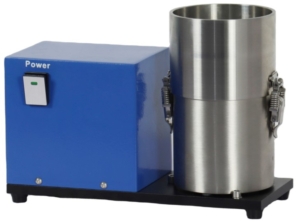

Types of Ball Mill

- Planetary Ball Mill

- Omnidirectional Planetary Ball Mill

- Vibratory Ball Mill

- Jet Mill

- Dual or 3D Movement Mixture

- Ideal for mixing dry powders

- Reducing particle size

- Options: Low temperature, Vacuum jacket

- RPM range: Up to 1000 RPM

- Ball and Jar materials: Zirconia / SS / Tungsten carbide / Nylon / Alumina / Agate

1 PPM Glove Box

The glove box is a high-performance, high-quality closed-loop working system that automatically absorbs water and oxygen molecules, purifies the working environment, and provides an inert atmosphere of 1ppm O2 and H2O that can meet your specific cleaning requirements. This system is an economical circulation purification system designed to meet customer research and development.

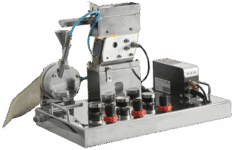

Mixing Equipment

- Mixer: Uniformly mix active materials, conductive agents, and binders to obtain a homogeneous slurry or dry powder mixture.

- High-Shear Mixture : Used for mixing high-viscosity materials with high uniformity.

- Mixing Volume: 50 ml – 100 l

- Dispersing RPM up to 6000 RPM (depending on the model, built-in vacuum pump)

- Temperature control through an external chiller unit

- Double planetary mixture with disperser and impeller

- Desktop model to a large industrial model

–

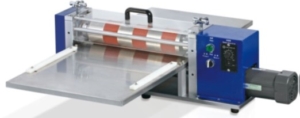

Apply layer(s) of slurry onto the current collector and dry it

- Extrusion Coater : Applies slurry to the substrate through extrusion.

- Doctor Blade Coater : This device uses a blade to evenly coat the slurry on the substrate with an easily adjustable coating thickness.

- Gravure Coater : An engraved roller applies slurry to the substrate, which is suitable for thin-layer coating.

- Roll Coater : Uses rollers to coat the slurry on the substrate uniformly, ideal for large-scale continuous production.

- Spray Coater : Uses nozzles to spray slurry onto the substrate, suitable for complex shapes and high-precision coating.

- Slot Die Coater : Applies slurry precisely onto the substrate through a slot die, suitable for high uniformity and high-precision coating processes.

- Desktop models to large industrial models

- Single sheet to Roll to Roll desktop version

- Coating method options: Blade, Transfer & Slot Die – Continuous, intermittent & stripe Pattern

- Built-in heater and exhaust system, PID temperature control up to 150°C

- Customizable heating zones

- Range of coating width: 50 mm – 900 mm (approx.) & a wide choice of coating length

- Options: Edge rectification, tension and speed control

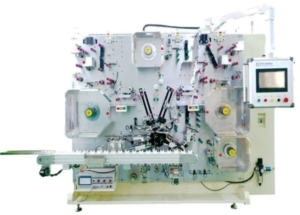

Roll-to-Roll Coating Machine

Compress the electrode to a desired thickness/density.

- Desktop to large industrial models

- Single sheet or R2R desktop version

- Electric heating/oil heating / without heating options (PID Temperature control)

- Mechanical / Hydraulic pressing, optional servo motor gap control

- Wide choice of specific pressing width: 100 – 900mm

- Edge trimming and dust collection

- Asymmetric rolling press for dry electrode fabrication

- Edge rectification, tension and speed control

Dual Chamber Vacuum Drying Oven

3-Chambers Vacuum Oven

- Precision digital display electric cell (Supercapacitor) shaping machine

- 60 battery supercapacitor cell (Diameter ~ 57mm, Length: 50 ~ 204mm, Customizable)

- The resistance test function can be installed (optional), and the detection range can be set

- PLC control standard product short-circuit test function and screening defective products

- High-precision guide pillar guide sleeve is used for guidance

- Adjustable height (40 – 150 mm) of the supercapacitor, the cylinder speed and shell penetration depth

- Optional high-frequency heating into the shell, suitable for an interference fit between the shell and the positive current collector

- PLC control, human-machine interface display, simple and convenient operation

- Detectable Masses: H2, He3, He4

- Automatic: Alert, Zero Adjustment, Calibration

- Handheld remote control unit

- Maximum print Area: 600 mm x 400 mm

- Semi-Automatic / Fully Automatic

- Touch panel controller

- Customised Screen Design

- Optional: Camera Vision System

Handheld disc Cutter

Handheld disc Cutter

Environmental Chamber: Battery Safety Measurement

1. Desktop constant temperature chambers

-

Desktop model: 25 L volume

-

Temperature range: 15 °C – 60 °C

-

Supports maximum 32 channels

2. Large constant temperature chambers

-

Stand alone model: 200 L to 500 L volume

-

Temperature range: 10 °C – 85 °C or 0 °C – 60 °C

3. High low temperature chambers

-

Temperature range: RT to 150 °C / (-70 °C, – 40 °C, -20 °C) to 150 °C

-

Volume: Up to 1000 L

4. Optional integrated battery testers / Explosion and automatic fire extinguisher

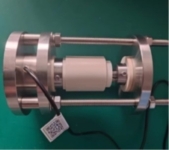

Split Test Cell

Split Test Cell

Three electrode test cell for battery materials

- Structure: SS304

- Cathode disk: 15mm dia or less

- Anode disk: 15mm dia or less

- Li Reference ring: OD 26mm x ID 19mm

- Size: internal diameter: 12mm

- Total length: 105mm

- Total height: 65mm

- PTFE intermediate: 66mm

- The lithium sheet can also be pressed by the cylinder at the middle step as the reference electrode.

- Material: stainless steel 316.

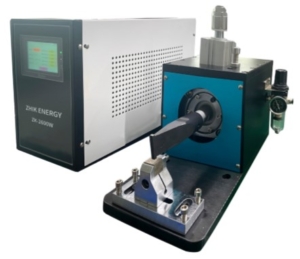

Solid State Battery Testing Device

Transfer fixture, Insulation mold, Temperature controller, Pressure sensor & Digital display meter

- PEEK (Optional Si3N4 for heating) sleeve

- Die diameter: 10mm, 20mm, 30mm (inner) and 40mm (outer)

- Temperature: Up to 300 °C

- Pressure range: 0 – 150 MPa

- Bottletop Dispenser: 0.5 – 50 ml capacity range

- Electrolyte Filling & Vacuum Diffusion (Cylinder / Pouch Cell): Liquid injection volume: 0.2 – 3L (Adjustable)

- Electrode Crimping / Punching Machine: Coin, Pouch & Prismatic Cells

- Desktop single sheet to production-level R2R models

- Easily replaceable punching die of custom-made dimensions

- Fully automated R2R models with vacuum cleaning, edge rectification, CCD detection of electrode quality for prismatic & pouch cell

Supercapacitor crimping machine

Slit / cut electrode sheet to strips of desired size

- Electric heating, oil heating or without heating option

- Single sheet, R2R desktop version

- Edge burr ≤ 12 μm

- Mother roll width up to 900 mm

- Slitting speed control

- Easy installation of the slitting die for different slitting widths

- Edge rectification, tension and speed control

- Desktop to large industrial models

Cutting Equipment: Used to cut pressed electrode sheets into appropriate sizes as needed.

![]()

- Electrode punching used for coin, pouch and prismatic cell

- Desktop single sheet to production-level R2R models

- Easily replaceable punching die of the user’s dimensions

- Fully automated R2R models with vacuum cleaning, edge rectification, and CCD detection of electrode quality for pouch and prismatic cell

- Smaller R2R version for the Laboratory is available

Electrode Die Cutting Machine

Electrode Die Cutting Machine

Form layers of Anode, Separator, and Cathode into the form of the pouch & prismatic cells

- Semi-automatic and fully automatic versions

- Wide choice of electrode width and length

- Automatic electrode pickup and placement for the desktop Z-Stacking machine

- CCD detection, Hi-pot testing for full auto models

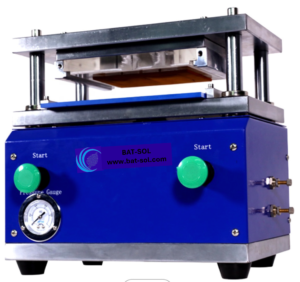

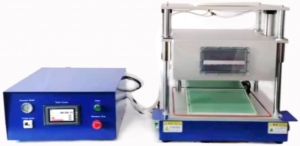

Hot Press Machine: The hot press shaping machine reduces battery thickness with a finalised design by pressure and heat, reducing the battery core short circuit rate and ensuring the consistency of the thickness of the finished batteries.

- Size of the hot plate can be customised according to the customer’s needs (200 mm to 3oo mm)

- Hot pressing machine’s temperature, time and pressure can be adjusted separately.

- Temperature of the upper and lower platens is controlled by the temperature controller

Joining of multi-layer electrodes, and/or tabs to collectors

- Different types of welding mechanisms with a wide choice of welding power and pattern

- Ultrasonic welder for TAB welding for cylindrical, pouch, and prismatic cells

- Spot welder for bottom welding and battery pack welding for cylindrical cells

- 3 in 1 desktop laser welder for prismatic cells

- Desktop semi-automatic models to a production-level fully automated line for cylindrical and prismatic cells

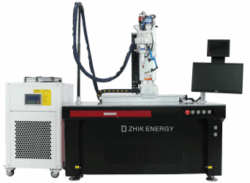

Laser Welding Machine

To create an indent on the neck of the case to allow for proper seal (after inserting the cell core)

Cylindrical Grooving Machine

- Used for lithium polymer battery pouch cell cup formation of different sizes

- Precise mould design, no crow’s feet and slumps at all corners and surrounding areas of the product after moulding

- Aluminium-plastic film & Cup Size: Max. L300mm x Max W250mm (can be customised according to requirements).

- Depth of the cup ≤ 6mm

- Tabletop manual, semi-automatic models for laboratory; glove box compatable

- Pouch Cell: Top & side sealing machine, Pre-sealing & Final sealing

- Fully automated production line machines.

- Top & Side Sealing before electrolyte injection

- Pre-sealing after electrolyte injection

- Vacuum stands for the electrolyte diffusion and degassing

- An industrial protocol for pouch cell formation has been adopted for laboratory scale.

- Formation process under PID controlled constant pressure and temperature on the pouch cells.

- Squeezes out gas from every corner, shortens formation time & battery production cycle and reduces labour

- Functions: Heating, temperature control, charging, data connection, communication, safety protection and smoke alarm

Winding Equipment: Used for electrode sheets to form cylindrical cells.

- Precision winding of 18650, 26650, 21700, 32650 Cylindrical Cells

- Semi-automatic and fully automatic versions

- Auto separator winding with tension and rectification control in all models