1] Single station Glove Box

Description:

Description:

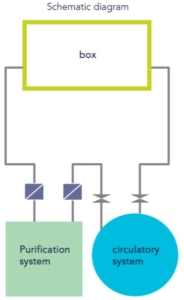

A glove box is a high-performance, high-quality closed-loop working system that automatically absorbs water and oxygen molecules, purifies the working environment, and provides an inert atmosphere of 1ppm O2 and H2O that can meet your specific cleaning requirements.

It includes a closed box, a transition chamber, a rotary vane vacuum pump and a circulation purification system integrated with a microcontroller operation

panel.

Working Principle:

While the working gas circulates through the purification column, the moisture and oxygen contained are adsorbed and returned to the tank. The water and oxygen content in the working gas will gradually decrease, and finally, the target of less than 1 ppm is achieved. The purification column will become saturated after a certain period of circulation. And, It can be regenerated and reused.

Specifications:

Box: Glove Box

Material : Stainless steel 1.4301 (SUS type 304), thickness 3 mm

Dimensions : 1200mm(L) x 750mm(W) x 900mm(H)

Volume : 0.8 m³

Front Window : Operation surface with inclined design, detachable 8 mm safety tempered glass front window, good wear resistance,

corrosion resistance and good light transmission, the sealing ring adopts 3/8 inch thick OMEGA sealing ring

Dimensions: 1123mm(L) x 839mm(H)

Glove Mouth : Hard aluminum alloy material or polyacetal material (optional). Bore 220 mm, O-ring seal

Gloves : Gloves caliber 8″, length 32″, thickness 0.4 mm, butyl rubber

Filter : Outlet and Inlet Filters, Filtration < 0.3μm

Lllumination : LED lighting on top of front window

Leak Rate : Leak detection is based on the oxygen-containing method and pressure change method in ISO 10648-2: 1994 / EJ/T 1096- 1999 “Sealed Chambers –

Part Two: Tightness Classification and Related Inspection Methods”. The final acceptance test is carried out according to the standard of primary tightness < 0.001 vol%/h.

Rack : Material: stainless steel material, built-in 2 layers, height adjustable

Interface : The cabinet is equipped with 4 standard KF-40 interfaces, 1 power port (220V)

Backet : With swivel casters, height 950mm. Casters have the functions of leveling, moving, fixing, etc.

Gas Purification System

Purification Ability : H2O ﹤1ppm O2 ﹤1ppm

Purification Material : Copper catalyst, molecular sieve

Adjustment Device : Through PLC touch adjustment (heating, evacuation, purification, regeneration) the whole process does not require human monitoring.

Working Gas : He, N2 or Ar (gas cycle)

Includes : Circulation fan, Single purification column, Purge Valve, Filter, Regeneration system, Display system, & Vacuum system

Transition Cabin – Large & Small transition cabin, Cleaning System

Analyzer – Axygen Analyzer & Water Analyzer

Description:

Description: